Thanks to extensive experience in the demagnetization field, ICT is able to provide different demagnetization technologies according to the customer’s specific application. With a careful analysis of the project variables (such as the geometry and dimensions of the parts, the type of material, the transfer system and the production process, the productivity and the residual magnetism requirements) we can formulate proposals that are the most advantageous possible for the customer.

Thanks to patented technology and on-going improvements over the years, we offer electronic impulse demagnetizers that ensure very high performances. In most cases the electronic demagnetizers realize a minimum residual magnetism and extremely low energy consumption (on average 150 W), which is as much as 20-30 times lower than the consumption of other demagnetizers.

We furthermore propose demagnetizers with traditional technology that are suitable for other applications. Thanks to the special demagnetization coils construction, outstanding values are guaranteed in terms of residual magnetism, lower energy consumption and limited magnetic retention.

Among different products and solutions, ICT can offer:

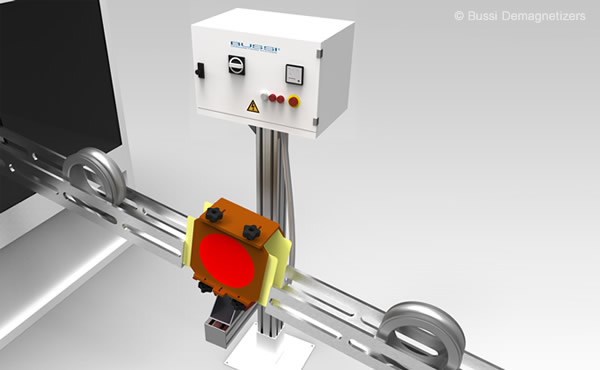

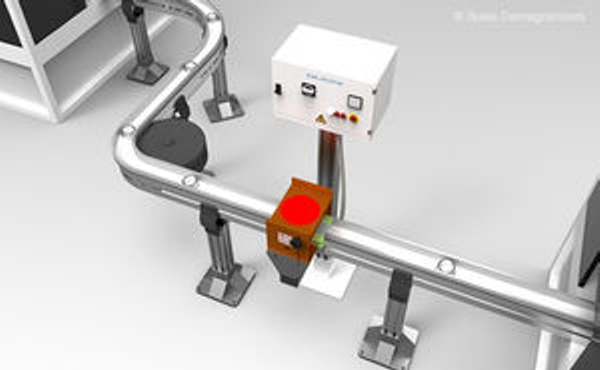

- Demagnetizers in line installed in flexible conveyor chains;

- Demagnetizers in line and off line with conveyor belt;

- Demagnetizers installed in automated processes with parts handling by robot;

- Off line and manual demagnetizers for the demagnetization of single parts or parts placed in washing and transport containers;

- Demagnetizers in line installed in rolling channels;

- Contact angle measuring machine for ball bearings.

Here below the main characteristics and performances of our demagnetizers:

- Minimum residual magnetism: the average residual magnetism obtained with our electronic demagnetizers is much lower than the limits of 2 A/cm that have been set by the best bearings and auto parts manufacturers;

- Minimum energy consumption: the average energy consumption of our electronic demagnetizers is between 100 and 300 VA, while the common tunnel demagnetizers have a considerably higher consumption between 1 and 25 KVA;

- High degree of demagnetization value repeatability: results of demagnetization are always repetitive and constant over time;

- Easy parts transfer without magnetic retention: the capacity discharge technology – where the energy necessary for the demagnetization is concentrated in a short impulse – guarantees an easy transfer of the parts without any magnetic retention;

- High degree of reliability and durability: meticolous design of each part and use of high quality components guarantee the maximum efficiency over time even when the production rythms are high;

- Very high productivity: the cycle time is between 2 and 20 seconds, according to the application, but in some cases cycle time of 0.8 sec are possible;

- Almost zero maintenance;

- Easy integration in line and exchange of interface I/O: possibility of programming dedicated signals for in line communications and installations;

- Easy installation;

- System modification and overhaul: after verification by feasibility study, it may be possible to overhaul exhisting systems to reach new customer requirements and economic savings.

We can always support to chose the best fit products for your own needs. Just get in touch with us directly at info@consulting-trading.com or through the form below “Request a Quote” to explain your needs. We will provide our feedbacks within a very short time.