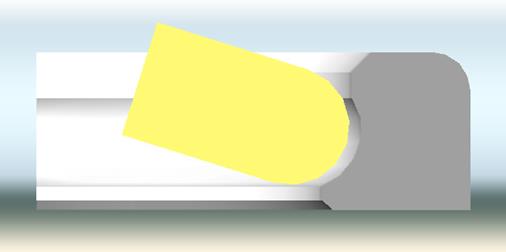

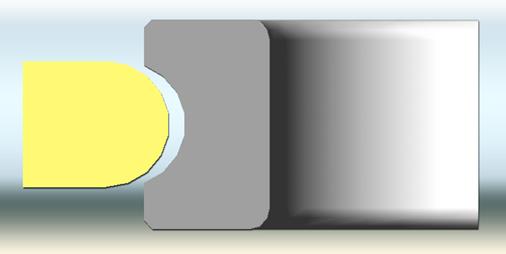

Superfinishing machines for raceway of ball bearings ring: for inner rings (model MTH 80 2 H- O – G) and for outer rings (model MTH 80 2 H – I –G)

- Steel base welded, stabilized thermically and worked.

- Two honing heads, one for the first operation (rough lapping) and the second one for fine lapping.

- Each station consists of workpiece slide, work spindle, spindle for lapping stone, oscillation control unit and pneumatically actuated pressor.

- Between the two honing heads the elevator for rings transfer is located, from the first to the second head.

- The electrical cabinet and the pneumatic panel are positioned on the back side of machine.

- The lapping machine is provided whit a hydraulic control unit for the workpiece slide.

- Electrical cabinet with MITSUBISHI Q series and GOT 2000 operator panel touch screen 10,4 “ colour. HMI is as per our special software to manage the machine and in English

- One set of tooling to test the machine.

- Safety cover to avoid any leakage and to protect the safety of workers, as per CE standards.

- Machine book and all technical documentations in English language.

External Ring Lapping

Internal Ring Lapping

Honing cell for raceway of outer rings ball bearing , model MTH 130- O- G- 2H

The honing cell is made by two single honing machines, installed in a steel base and with one elevator between them. Each machine is made like it follows:

- Machine bed and vibration isolation pads

- Work head slide managed by servo motor, ball screw and linear bearing slide

- Work head spindle with high precision bearing supported, managed by motor and frequency converter

- Linear oscillation spindle able to receive the honing stone holder, with oscillation stroke from 0 to 3 mm. The oscillation speed is adjustable up to max 1500 rpm

- Loading and unloading device is managed by pneumatic cylinder.

- Pressure clamp to fix the rings in working area, by pneumatic control. Force of pressure by servo valve.

- Fluidic system according to EEC standards.

- Electrical cabinet with SIEMENS S7 300 PLC and OP operator panel. HMI is as per our special honing software to manage the machine and is in English

- One set of tooling to test the machine.

- Safety cover to contain the leakage and to preserve the safety of workers, as per CE standards.

Machine book and all technical documentations in English language.

Honing cell for raceway of ball bearings inner rings, model MTH 110- I- G- 2H

The honing cell is made by two single honing machines, installed in a steel base and with one elevator between them. Each machine is made like it follows:

- Machine bed and vibration isolation pads.

- Work head slide managed by servo motor, ball screw and linear bearing slide.

- Work head spindle with high precision bearing supported, managed by motor and frequency converter.

- Linear oscillation spindle able to receive the honing stone holder , with oscillation stroke from 0 to 3 mm. The oscillation speed is adjustable up to max 1500 rpm.

- Loading and unloading device managed by pneumatic cylinder.

- Pressure clamp to fix the rings in working area, by pneumatic control. Force of pressure by servo valve.

- Fluidic system according to EEC standards.

- Electrical cabinet with SIEMENS S7 300 PLC and OP operator panel. HMI is as per our special honing software to manage the machine and is in English

- One set of tooling to test the machine

- Safety cover to contain the leakage and to preserve the safety of workers, as per CE standards.

Machine book and all technical documentations in English language.

Honing machine for tapered roller of bearing TRB

- Machine bed and vibration isolation pads

- N° 2 Drum to feed rollers from inlet to outlet of the machine

- Oscillation unit managed by eccentric and servo motor

- N° 10 honing stone holder to fix the right sequence of honing stones from rough to finish grade

- Fluidic system in accordance to EEC standards

- Machine pre-arrangement for connection to a central coolant system .

- Safety cover to avoid any leakage and to protect the workers, as per CE standards.

- Electrical cabinet with SIEMENS S7 – 320 and OP operator panel. HMI is as per our special grinding software for manage the machine and in Italian and English language.

OPTIONAL:

Special tank for honing oil filtration and to supply the honing machine, 400 litres capacity with magnetic and paper filtrations.

All the lapping machines supplied through ICT can be designed and developed according to the specific customer demands. Whatever is your request and technical expectation about your lapping needs, just get in touch with us at info@consulting-trading.com or through the contact form of this page to provide your inputs. We will provide our feedbacks in a very short time.