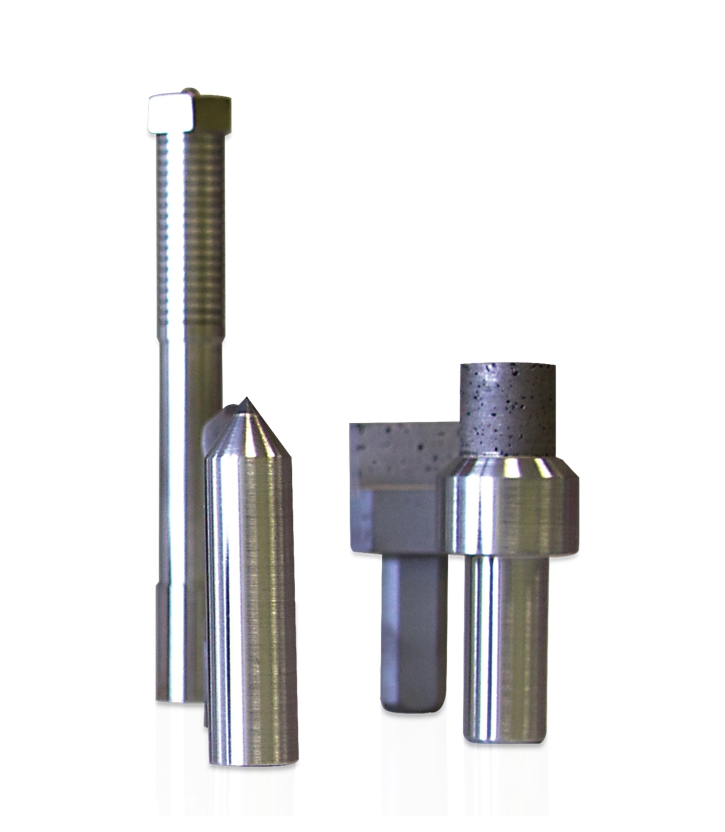

ICT offer covers the whole range of stationary diamond dressers:

- Single point

- Multi point

- Impregnated

- Chisel type

- Cone type

- Blade type

- Crown type

- In mono crystalline diamond

Single point dressers are used for OD and side dressing of conventional wheels. They can be used on cylindrical grinders, bore grinding wheel dressing, surface grinders, tool and cutters, larger profiles, male and female generations on wheels, or remove the existing profiles (random dressing). They can also prepare the wheel for a fresh form.

Multi point diamond dressers are used for conventional large diameter and lengthy dressings, straight dressing, side dressing, angle dressing. They can be used where consistent good surface finish and frequent dressing cycles on suitable machines are required.

Chisel type dressers are manufactured from special machined diamonds, with included angles ranging from 35° to 70° and a minimum radius of 0.08 to 1.0 mm. They can be used on conventional wheels for profile generation, male or female, step forming, retaining sharp corners (female on wheel) with a programming system or with template (copying). They are suitable for use on thread grinders, special purpose machines, internal grinders, optical profile grinders, angular grinders and cylindrical grinders.

Blade dressers are produced from special needle diamonds. To hold such needle diamonds, bonding system is arranged in a pattern.

They are ideal for applications where consistent surface finish and longer life are important. They can be used for profile generation (male or female), side dressing, angular dressing and OD straight dressing.

Impregnated dressers are produced from special diamond grits. Bonding system holds the grits firm.

They are manufactured in cylindrical, cube and rectangular shapes, with different grit sizes and concentrations. These dressers can be used where longer life, frequent dressing cycle and consistent surface finish are required. They are suitable for use on centreless grinders of larger diameters and lengthy dressing cycles.

Cone type dressers are manufactured from special shaped diamonds, with include cone angle ranging from 60° to 85° and nose radius ranging from 0.1 to 2.0 mm. they are suitable for consistent dressing because of their cone shape and can be used for OD dressing, side dressing and angle dressing on suitable machines.

In ICT crown type dressers 24 or 36 number of high quality diamonds are set in geometrical patterns. The arrangement to index the diamonds ensures a long life along with efficient wheel dressing. The dressing forces are spread out since more than one diamond comes in contact with the grinding wheel.

Crown diamonds provide the most economical and accurate dressing option.

Industries are more and more opting for new types of conventional bonded wheels. Down time on high end machines are no longer acceptable, especially in continuous process lines. To match these needs, mono crystalline diamonds (MCD) are replacing traditional natural diamond dressers. Life and consistency of MCD dressers are from 5 to 7 times higher in comparison to the natural diamond dressers.

Please get in touch with us at info@consulting-trading.com or through the contact form that you find here below to see what we can do for you: one of our technicians will provide feedbacks to you within a very short time.