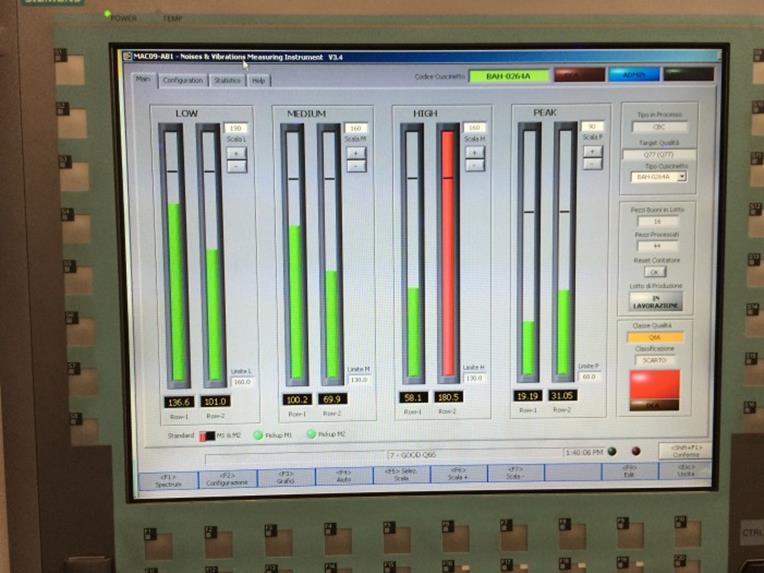

ICT is able to provide a very innovative system for measurement of both waviness (e.g. of ring’s groove) and noise (of bearings). Both systems are based on the acquisition of measurements in velocity (micron/sec) and in the elaboration of the signal in frequencies bands, with calculation of root mean square value through proper algorithm.

The velocity method has the advantage to get higher resolutions/ precisions for high frequency defects respect to the dispacement method (micron) used in certain competitors equiments and available expecially for the waviness measurement of rings geometry. This means that ICT equipment is able to guarantee more information about the level of finishing of rings’ tracks than what can be done by other systems.

In similar ways, the ICT bearing noise equipment performs better than other dB (i.e. acceleration, micron per square second) measurement methods on the lower frequency bands, guaranteeing a better info about the basic geometry and precision of bearings. Furthermore, a special algorithm allows the calculation of any temporary noise generated in the bearings, for instance, by localized defects on rolling elements or on ring groove or by dirt parclicles in the grease: such not constant noise contribution is measured by the “peaks” parameter.

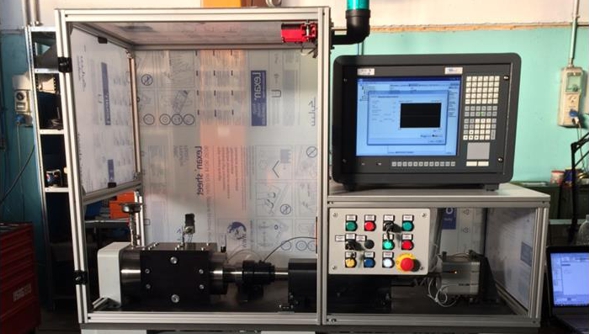

ICT can customize following equipments:

- Waviness control machine for rings (IR and OR);

- Waviness control machines for balls and rollers;

- Bearing noise control machine (off-line and in-line, with and without axial load).

In case of bearing noise control machine, it is possible to analyze the signal in frequency and compare it with the natural noise frequencies of the individual components of the bearing. Such type of FFT analysis allows to statistically determine which are the components (IR, OR, rolling elements, cage, dirt) that mostly contribute to the bearings rejection.

Furthermore the system allows the user to set a special customized mask – to be added to the standard limits for the different frequency bands – to generate an additional control of bearings quality.

We can always support to chose the best fit products for your own needs. Just get in touch with us directly at info@consulting-trading.com or through the form below “Request a Quote” to explain your needs. We will provide our feedbacks within a very short time.