For the bearings industry ICT is able to offer best in class products with the complete range of solutions for all type of bearings and bearing components.

With all the latest advancements in the field of automobiles and machine manufacturers, the function of bearings are more and more crucial to guarantee proper performance of these applications. In this context, the role of grinding wheels is fundamental.

Track grinding wheels, for instance, must maintain form to ensure profile accuracy of the groove of inner ring. This ensures that the wheels are dressed less often, leading to significant improvement in productivity and consistency of the process. ICT offers track grinding wheels made with a special fusible glassy bond with sharp abrasive grain combination that ensures form holding while offering high material removal rates in a high contact area application. An advanced manufacturing process ensures that the wheel’s hardness is consistent through the wheel life and highest levels of safety are maintained.

The combination with special bonded technology and best abrasive technology in our wheels can guaranty high material removal rate also in high contact area without any risk of micro burning and long wheels life.

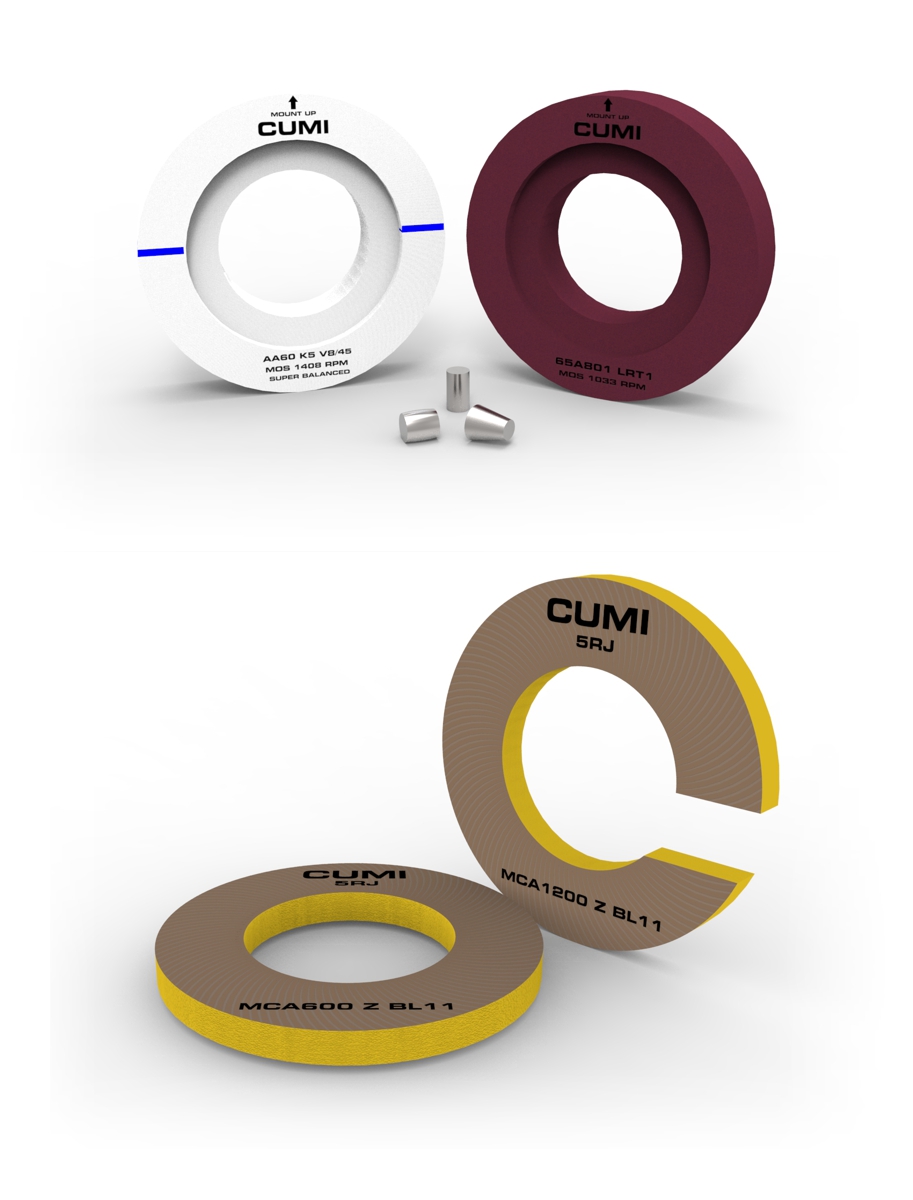

For the grinding of the bearing rings faces ICT can propose different solutions of resinoid F-Type wheels designed for the complete range of double disc machines. We are in condition to suggest the best solution in function of the dimension of the rings and of size of the faces to be ground. In case there is a significant difference in the rings faces area between the 2 sides of ring (like, for instance, in taper roller bearing rings) ICT can propose different grain sizes and/or abrasives in order to increase the efficiency of the machine.

Our resinoid wheels are available with different abrasives (in aluminium oxide for standard application, in ceramic abrasive for high performance or in both in a full range of Grain size) and in a wide range of bonds (including phenolic, magnesite and polyester).

ICT wheels are proven to perform at high feed rates and material removal applications while meeting stringent quality requirements in terms of size tolerances, heat generation and surface finishes, thanks to a special technology of grain-bond combination, which ensures free cutting. Physical features like coolant slots, through holes and honeycomb structure aid in taking the performance of the wheels to the next level.

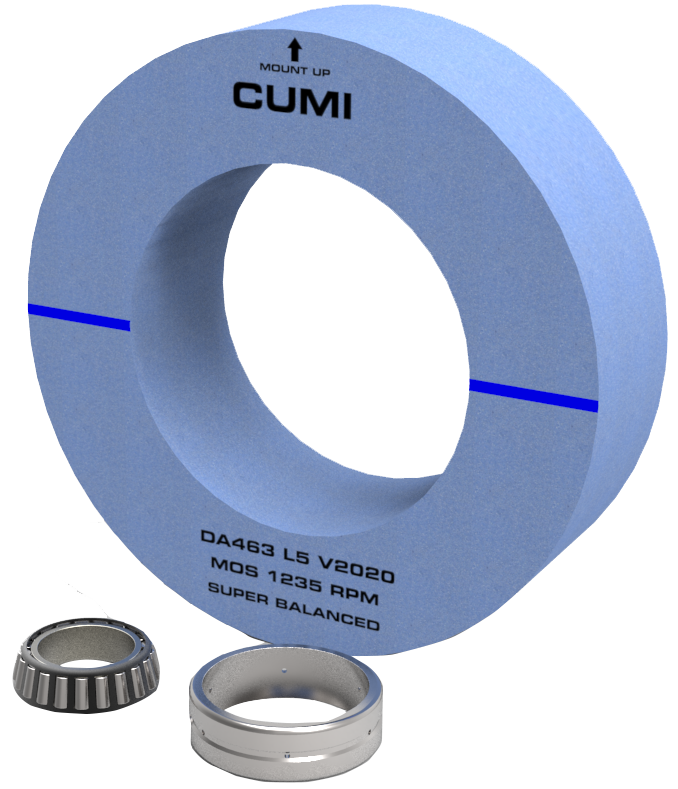

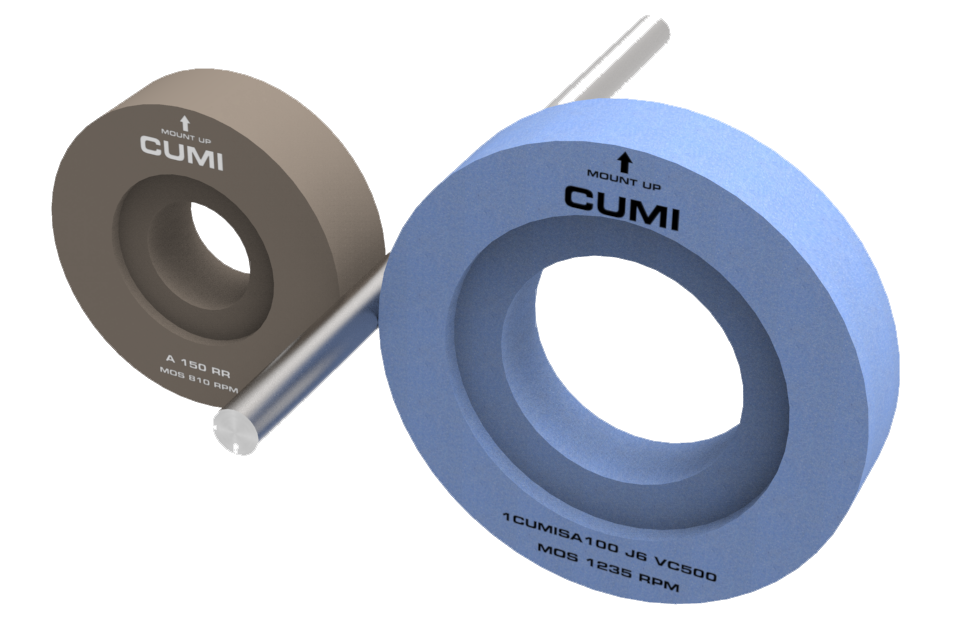

For the rings external and internal grinding we have a complete range of wheels and abrasives to offer, suitable for full range of grinding machines available on the market and for all types of grinding (plunge, infeed and centreless). In this segment ICT can offer best in class solutions that have no comparison in the market in terms of wheels durability and productivity.

Through our R&D center in Chennai (India) we are in condition to suggest the correct wheels and the customized solution to cover all your technical parameters.

Our vitrified wheels are available in a full range of abrasive: in aluminium Oxide AA, 12A and also in RA and RAA (pink aluminium oxide) designed to keep all types of profile for very long time; in monocrystalline sharp aluminium oxide 53-55A for high performance applications; in ceramic abrasive MCA-CUMISA for superior expectations.

ICT regulating wheels (rubber wheels) are without comparison in the market, thanks to the long terms experience of our business partner in making them. The calendaring process enables excellent control in size and finish of components being ground. Special features assured by these wheels are a longer wheel life, a lesser dressing frequency, a superior form retention and an excellent surface finish. ICT covers the full range of dimensions for these rubber wheels.

ICT’s versatile range of bore grinding wheels is used for grinding a variety of components that require size generation, fine surface finish and fast stock removal. We also offer value added services like sulphur treatment for lubrication and cooler cutting action. These wheels are characterized by sharp aluminium oxide grains for excellent cutting action and by crystal bond for form holding (V500).

For the bearing rollers grinding ICT can offer a complete range of wheels and abrasives, suitable for the whole range of machines and both for centreless grinding and plunge grinding. In this segment we have best in class solutions that have no comparison in the worldwide market.

Our technicians in Chennai R&D center are in condition to suggest the correct wheels and the customized solution to cover all customer technical requirements.

ICT vitrified wheels are available in a full range of abrasive: in aluminium oxide AA, 12A and also in RA and RAA (pink aluminium oxide) designed to maintain all types of profiles for very long time; in monocrystalline sharp aluminium oxide 53-55A for high performance; in ceramic abrasive MCA-CUMISA for superior results; in silicon carbide C and GC.

For the end face grinding of taper, cylindrical and spherical rollers ICT has different solutions of resinoid F-Type wheels (designed for the complete range of double disc machines) and vitrified cup wheels (for taper rollers end face grinders).

With a very long experience in the field, we are in condition to suggest the optimal solution in base to the roller dimensions and to the face area to be ground.

ICT resinoid and cup wheels are available in different abrasive types: in aluminium oxide for standard applications (A, SA, AA), in ceramic abrasive for high performance (CUMISA, MCA) and in a combination of the above types, all in a full range of grain sizes.

Only few manufacturers in the world are in condition to produce grinding and lapping wheels for bearing steel ball. Our partner is one of the best in the world since many years.

Our grinding vitrified wheels for steel balls are a concentrate of technology and raw material purity, available in best silicon carbide abrasive able to reach the Z hardness (the highest possible grade). Both chrome steel and stainless steel balls can be ground through such wheels. In special process conditions, it is also possible to grind ceramic balls, like silicon nitride and silicon carbide ones.

Our offer for balls manufacturing includes lapping and superfinish resinoid wheels, with closely graded aluminium oxide grains for superior surface quality, unique inside out hot press technology for ensuring consistency and modified resins to achieve high material removal rate and low wheel wear.

Widely used in bearings industry but also in tools manufacturing, ICT’s superfinishing stones are available in vitrified and resinoid bond, both with aluminium oxide and silicon carbide abrasives and with grain sizes from 400 to 1500 (Fepa). Full range of dimensions is available.

Please get in touch with us at info@consulting-trading.com or through the contact form that you find here below to see what we can do for you: one of our technicians will provide feedbacks to you within a very short time.